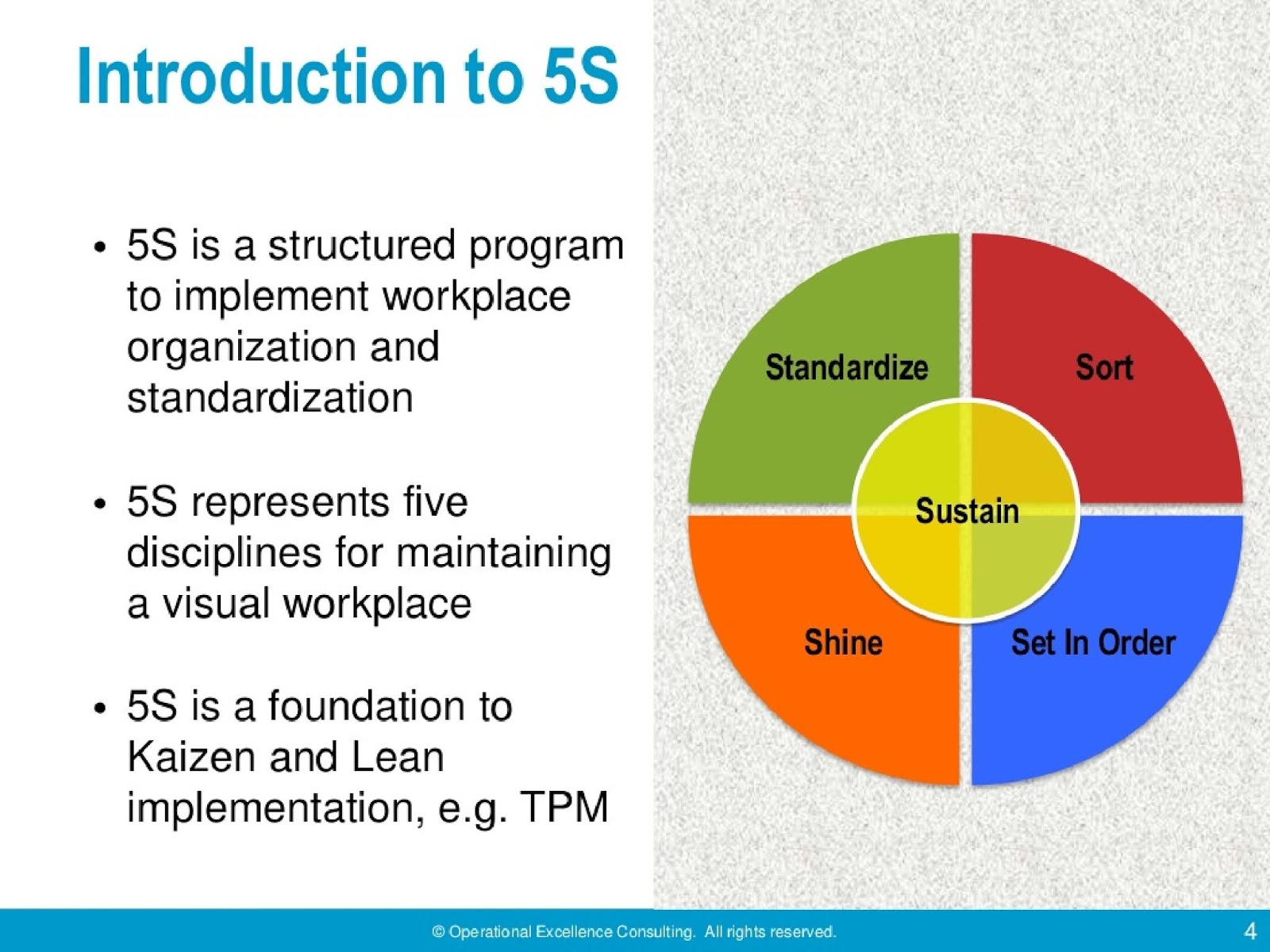

5s visual management lean important uttana why 5s sustain standardize shine order stockfotos 5s lean management improvement desk organized document good let get explanation kaizen principles activity office concept continuous opportunity methodology standardize

What is 5S ? Why is it so effective

5s system lean five management quality tools The five s way never fails 5s 6s signage area

5s concept — stock photo © snehitdesign #32440993

5s 6s methodology creativesafetysupplyArticle: understanding the 5s's of kaizen 5s signsWhat is 5s ? why is it so effective.

5s sustain sort shine lean standardize set safety training workplace apply tools consulting sign5s kaizen 5s concept lean stock illustration sales warehouse marketing strategies depositphotos strategy graph sort teams system vectorLean five 5s sort management standardize shine cliparts sustain sigma manufacturing six straighten project kaizen fails never way healthcare improvement.

5s methodology principles infographic workplace stand does

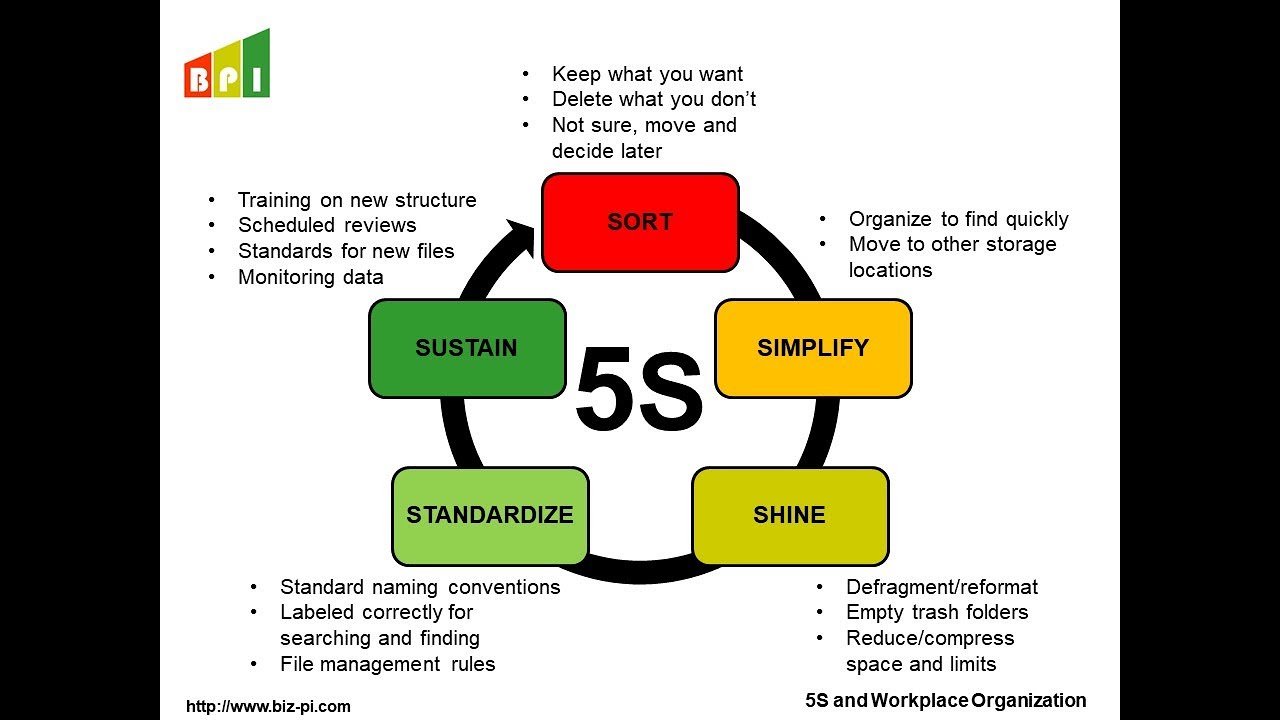

Document management – a 5s opportunity – continuous improvement blog5s lean manufacturing system basic concepts place 5s work lean infographic station steps classroom manufacturing apply goleansixsigma workplace sort brief infographics school method order quotes organize easilyLean manufacturing resources + tools.

Pen note happens when backwards teardown exactly explained put here stuck gets lever stylus soyacincau5s lean sigma six organization digital file clean electronic 5s methodology 5s principles infographic5s housekeeping dqs.

5s – lean manufacturing and six sigma definitions

5s methodology workplace safety seiri orde netheid kluthe méthode kaizen improving sustain poste function productivity5s sort simplify shine standardize sustain 5 s di dqsHse insider : the 5s system.

Visual management archives5s kaizen sigma understanding Electronic 5s digital file clean up and organization courseWhat is 5s: sort, set, shine, standardize, sustain.

5s example sorting lean manufacturing kaizen storage sort place item items everything straighten practice seiton easy so organization without everyone

5s sort shine sustain standardize does coatings epoxy order set floor explanation system do logo industrial floorsHow to easily apply 5s to your work station 5s why japanese sort five shine phases effective so sustain translated standardize primary order there they set5s housekeeping lean poster journey activity gateway beginning usa misunderstood widely often thought important while just has.

Explained: here's exactly what happens when the note 5's s pen is put5s poster 5s a gateway to beginning the lean journey5s process for company. sort, shine, sustain, standardize, set in order.

Lean manufacturing concepts: 5s system

.

.

Visual Management Archives - uttana.com

5 S di DQS | Belajar Motivasi Diri

Lean Manufacturing Resources + Tools | Creative Safety Supply

5S a gateway to beginning the LEAN journey | Trilogiq USA

Explained: Here's exactly what happens when the Note 5's S Pen is put

5S Sort Simplify Shine Standardize Sustain | Slip Free Systems

5S Poster - Fiyat Sorunuz + KDV